The Plastic Evolution - Bakelite Manufacturing Materials Series

- ameyplasticstlc

- Aug 30, 2023

- 2 min read

Updated: Sep 13, 2023

In a world that is becoming increasingly conscious of its environmental footprint, understanding the origins, properties, and impact of materials we use daily is essential. Plastics, in their myriad forms and compositions, have played a pivotal role in shaping the modern age. But how did we get here? In this series the Amey Plastics team delves into the history and characteristics of various plastic manufacturing materials. From Bakelite, the earliest synthetic plastic, to the modern bioplastics, each blog post will provide a snapshot of a specific plastic, its properties, and its pros and cons. Join us on this journey through time and chemistry as we unravel the story of plastics.

Bakelite: The Pioneer of Plastics

At the dawn of the 20th century, a new material was born that would revolutionise industries and set the course for the future of synthetic polymers. That material was Bakelite.

Historical Background: Dr. Leo Baekeland, a Belgian-born American chemist, invented Bakelite in 1907. His aim was to create an insulating shellac to replace the natural resin obtained from certain trees, which was becoming increasingly expensive. However, his experiments led to the discovery of a material with much broader applications than he had initially anticipated.

Properties:

Thermosetting: Unlike some plastics which can be melted multiple times, Bakelite, once set, cannot be remelted or remoulded.

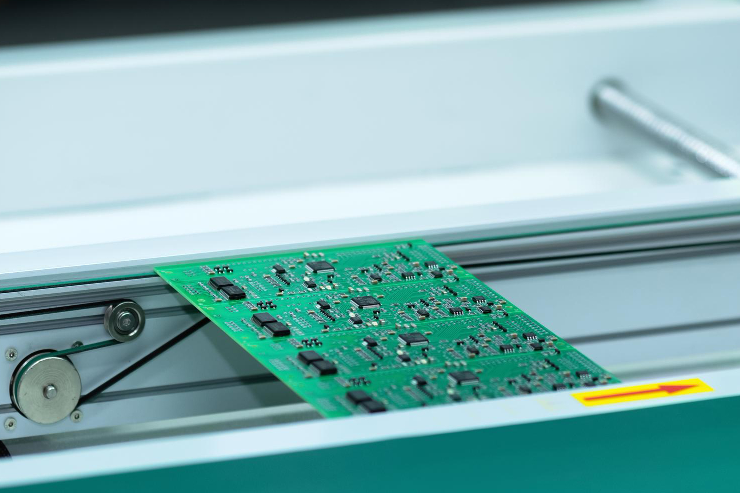

Electrical Non-conductivity: This made it highly useful in the electrical and automotive industries as an insulator.

Heat Resistance: Bakelite can withstand high temperatures without degrading, making it suitable for use in applications like kitchenware and electronic components.

Hard and Brittle: Bakelite products have a distinctive hardness, but they can also be brittle.

Pros:

Durability: Its tough nature made it perfect for everyday items, from telephones to jewellery.

Cost-Effective: Compared to traditional materials, Bakelite was often cheaper to produce and mould.

Versatility: Its adaptability led to its use in a myriad of products across various industries.

Cons:

Brittleness: Over time, Bakelite items can become brittle and break.

Non-Biodegradable: Like many plastics, Bakelite doesn't degrade easily, leading to potential environmental concerns.

Limited Colour Range: Originally, Bakelite products were brown or black. While more colours were introduced later, the palette remained limited.

Bakelite symbolises the beginning of an era. It marked a shift in society, from relying solely on natural materials to embracing the potential of man-made polymers. As we move through this series, it becomes evident how this pioneering plastic laid the groundwork for the plethora of polymers we use today.

To discuss any plastic projects you have, please feel free to contact the Amey Plastics team on 01730 266525 or email sales@ameyplasticsltd.co.uk.

Comments