The Impact of Plastic Injection Moulding on the Electronics Industry. How Precision Moulding Powers the Devices We Use Every Day

- josh61940

- Oct 27, 2025

- 3 min read

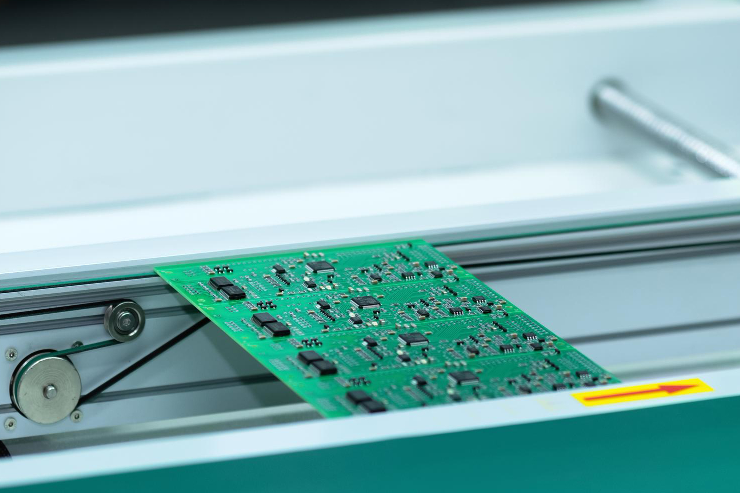

From smartphones and circuit boards to smart home systems and automotive electronics, plastic injection moulding plays a vital role in the world of electronics. It’s the process behind many of the sleek, durable and reliable components that make modern technology possible.

At Amey Plastics, we’ve built up considerable expertise through working with businesses across the electronics sector to produce high-quality moulded parts that combine precision, protection and performance.

That is why in this blog, the Amey Plastics team would like to shine a light on how injection moulding continues to shape this dynamic industry.

Read on to discover why we think plastic injection moulding is so important for the electronics sector.

1. Precision Manufacturing for Complex Components

Electronic devices require small, intricate parts that must fit together with absolute precision. Injection moulding offers the accuracy and repeatability needed to produce these components to tight tolerances.

Examples include:

Switch housings and control knobs

Connectors, sockets and clips

Cable management systems

Enclosures for circuit boards and sensors

The ability to create detailed and reliable parts at scale makes injection moulding indispensable to electronic product design.

2. Electrical Safety

The variety of plastics available to manufacturers, with their different array of properties, means there will be one that is ideal for your electrical components’ needs. Injection moulded housings and covers help prevent short circuits, moisture ingress and accidental contact with live components.

Common materials such as ABS, polycarbonate and nylon are often chosen for their multitude of properties, including durability, impact resistance and heat stability, essential in high-performance electronics.

3. Lightweight, Durable Enclosures

In consumer electronics and industrial applications alike, reducing weight without compromising protection is key. Plastic injection moulding allows manufacturers to produce lightweight yet strong enclosures that protect delicate electronic systems from dust, heat and impact.

Design flexibility also means housings can include built-in clips, seals and mounting points, reducing the need for additional assembly or fasteners.

4. High Volume Production at Consistent Quality

The electronics industry relies on high-volume production to meet global demand. Once a mould is created, injection moulding can produce thousands, or even millions, of identical parts with minimal variation.

This repeatability is vital for maintaining quality and performance consistency, particularly in components that must integrate seamlessly across multiple devices or product ranges.

5. Design Flexibility for Innovation

Today’s electronics require more than just function, they need aesthetic appeal and ergonomic design too. Injection moulding allows designers to experiment with different shapes, colours, finishes and textures, giving manufacturers greater freedom to align products with brand identity and user expectations.

It’s also compatible with insert moulding and overmoulding, allowing metal parts or circuitry to be combined directly with plastic housings for added functionality.

6. Supporting Sustainability in Electronics Manufacturing

As the industry looks to reduce environmental impact, injection moulding is evolving to support sustainability.

Recycled materials and bioplastics can be used in certain applications without compromising quality.

Optimised tooling and production processes help minimise waste.

Lightweight components contribute to energy-efficient product design.

At Amey Plastics, we actively explore these sustainable solutions, helping manufacturers meet both performance and environmental targets.

7. Partnering with Experts for Reliable Results

For electronics manufacturers, choosing the right injection moulding partner is essential. Precision, cleanliness and consistency all affect final product performance.

At Amey Plastics, our team has extensive experience producing high-quality components, from small technical parts to complex, multi-component assemblies. Our in-house design, tooling and production capabilities allow us to deliver accuracy, repeatability and reliability across every stage of manufacture.

Plastic Injection Moulding & Electronics Manufacturing Are Perfect Partners

Plastic injection moulding sits critically at the heart of modern electronics. It enables manufacturers to combine innovation with practicality, producing components that are lightweight, durable and precise.

And as electronics continue to advance, the partnership between engineering and injection moulding will only grow stronger.

Are you looking for a reliable UK-based manufacturing partner for your components?Strategically located in Hampshire, England, contact the Amey Plastics today team on 01730 266 525 or email sales@ameyplasticsltd.co.uk to discuss your project and discover how we can help you bring your designs to life with precision and efficiency.

Comments