The History of 3D-Printing

- Aug 13, 2021

- 3 min read

While 3D-printing may seem commonplace in today’s world, it wasn’t so long ago that it was quite literally the stuff of fiction.

From the pages of a book to machines now being in our own homes, 3D-printing has evolved quickly over a short period of time, and in this blog, we’ll detail that journey.

Humble beginnings

As previously mentioned, something similar to the process we now know as 3D-printing was mentioned in literature as early as 1945.

In a short story, American science fiction writer Murray Leinster detailed a construction process that used a robotic arm that produced plastic that hardens and followed drawn designs.

Similarly, it was described by writer Raymond F. Jones in a short story submitted to Astounding Science Fiction magazine in 1950.

Science Fiction Made Real

It was in the 1970s that a patent was filed for a machine, dubbed the Liquid Metal Recorder, that was very similar to today’s modern 3D-printing.

Inventor Johannes F Gottwald claimed the machine was capable of rapid prototyping and controlled, on-demand production of patterns.

It wouldn't be until a few years later that 3D-printing started to gather steam, not without a few hurdles still to navigate...

A Hesistant Start

Fast forward to 1981 and researcher Hideo Kodama invents two additive methods for producing 3D plastic items using a photo-hardening polymer.

Despite this breakthrough, there was no great interest, and the project is abandoned.

In 1984, the first patent for what we now know as SLA was filed by a team of French inventors. SLA, or stereolithography, is a 3D-printing method that prints three dimensional items in a layer-by-layer process using a photosensitive material, which is then exposed to ultraviolet light to harden it.

Although commonly used today, at the time the project was ultimately discarded as it wasn’t seen to have any viable business uses.

Another patent for SLA was filed just weeks later by American Chuck Hull, and unlike the French inventors, Hull managed to take the patent through to completion. Hull was also responsible for the development of the STL file format.

Originally developed for SLA 3D-printing, the STL file format is compatible with CAD (computer aided-design) software. The file describes only the surface geometry of 3D objects without any data on colour or texture.

There have since been other file types for developed for 3D-printing, but the STL file remains the most common and many consider it key to helping 3D-printing to reach the heights it has today.

The Evolution of an Industry

Over the next decade, several other 3D-printing methods were developed, such as SLS and FDM, as well as DMLS.

SLS, or Selective Laser Sintering, moulds nylon-based powders into solid and durable plastic.

FDM, or Fused Deposition Modelling, works similarly to SLA by creating layers of plastic fibre to create the object.

DMLS, also know as direct metal laser sintering works similarly to SLS but using a metallic powder as a material rather than plastic.

3D-Printing Today

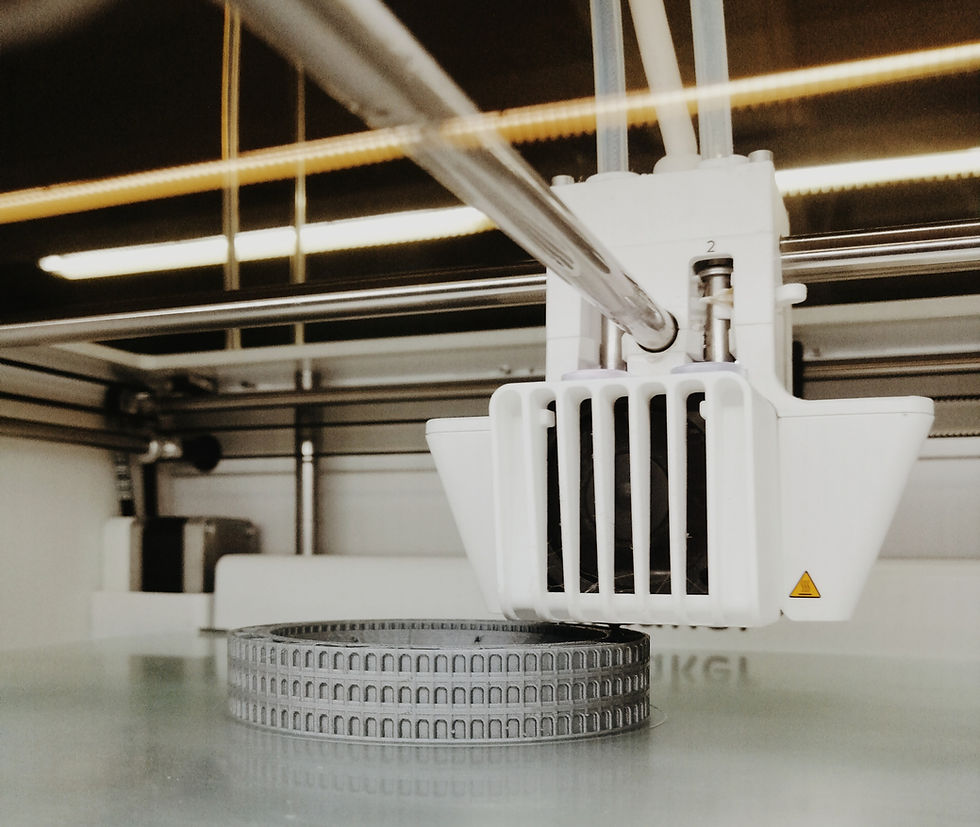

As previously mentioned, 3D-printing is now so wide-spread and accessible that it can be found in homes around the world, used either for hobbies or even for independent businesses.

The uses for 3D-printers has expanded rapidly, with a wide variety of products being made using the process, such as personalised medical implants and Formula 1 engine components

At Amey Plastics, we specialise in SLA 3D-printing and have helped guide many clients through their project, from concept to finished product.

If you have a project you’d like to discuss with us, contact us today by calling 01730 266525, or send an email to sales@ameyplasticsltd.co.uk.

Actually, 3D printing has evolved from industrial prototypes to accessible creative tools, shaping industries from manufacturing to entertainment. For hobbyists and enthusiasts, https://www.gambody.com/ offers a marketplace of STL files, allowing anyone to bring video game and comic models into the physical world. Exploring the history of 3D printing alongside practical applications shows how far the technology has come and inspires new ways to create tangible objects from digital files.

Festival fonts are perfect if you want your designs to feel lively and fun. I used festival fonts for a poster for a local music festival, and it made the text pop with energy and excitement. These fonts are great for event promotions, party invitations, or any project that needs to convey joy and celebration. They are readable but have enough personality to stand out on colorful backgrounds. If you want your design to feel upbeat and festive, festival fonts are a fantastic choice.